Excavator vs backhoe – Which machine would we recommend?

The success of a construction project depends on choosing the right equipment. Different machines can do the same job, but selecting the most appropriate machine would help finish the task in less time and at the minimum cost.

Excavators and backhoes are the two most commonly used construction equipment. Each piece of equipment has its specific usage and functions. If you are still determining whether an excavator or a backhoe is best for your project, the article will help you make the right decision.

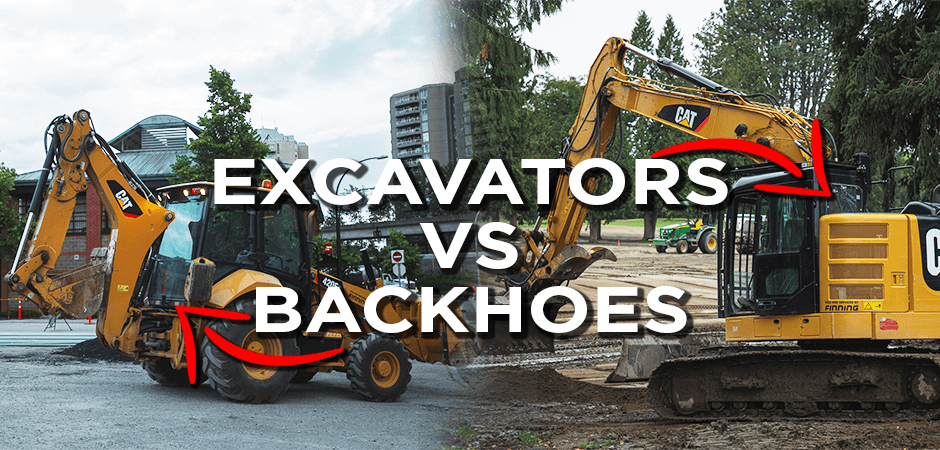

Backhoe vs Excavator

The primary use of both machines is digging, but each machine is suitable for a specific type of project. Always use an excavator if you are dealing with a large construction project or a heavy mining project. Similarly, an excavator will be the most suitable machine for heavy demolition projects.

For a project that needs moderate excavation but the construction site consists of several buildings located at a distance, a backhoe can be much more helpful owing to its smaller size and mobility. It can shift quickly between structures due to its small size.

If the construction site does not have leveled land, we can deploy an excavator with a track carrier to carry out the excavation. Excavators can have tracks or wheels, while the backhoes come only with the wheel option.

Backhoes are often used for smaller jobs like landscaping, residential excavation, and snow removal.

Key Physical Differences

One of the key differences between an excavator and a backhoe is the weight. On average, a standard excavator weighs around 45 tons, while a backhoe weighs 7.5 tons.

The size of an excavator is typically larger than that of a backhoe. The excavator consists of a cabin connected to an arm and a boom with a bucket. There is an undercarriage below the cabin that moves the machine.

The backhoes look very different from the excavators. Their cabin resembles a tractor cabin. On the front, there is a loader attachment. At the back, a boom and dipper stick is connected to a bucket, like an excavator.

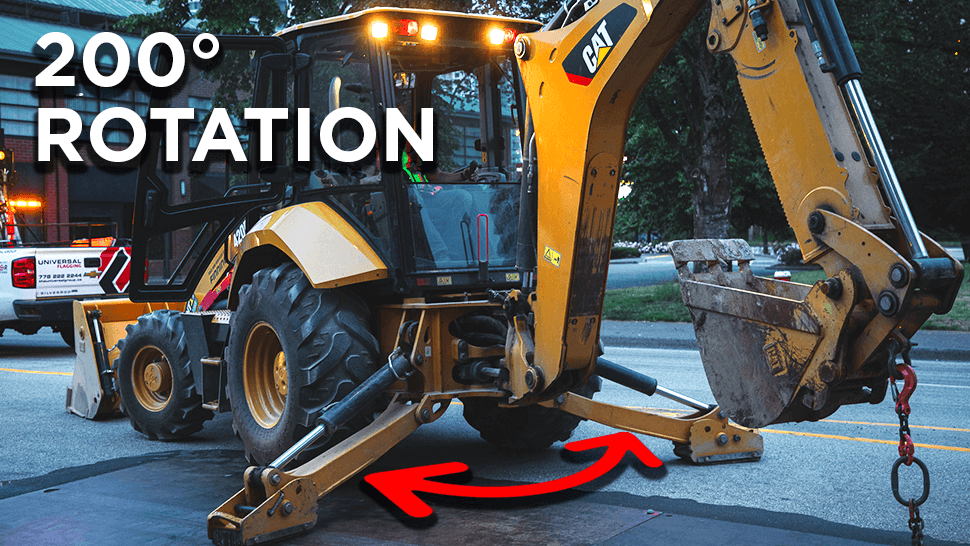

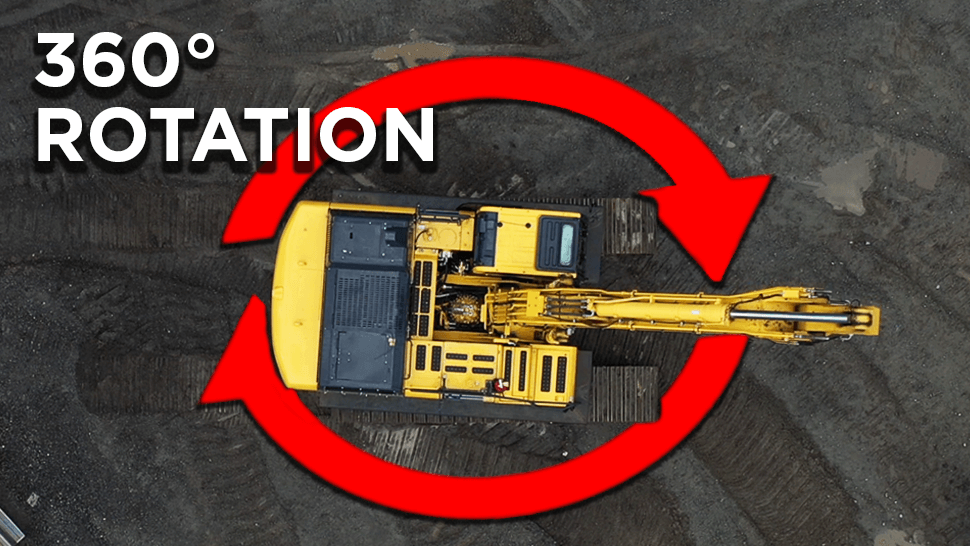

Another important difference between the two machines is the rotational range. An excavator’s entire cabin can move 360 degrees, while the backhoe’s arm can rotate around 200 degrees only.

Control Systems

Like any rental, always check its physical condition before you sign anything. Ask the rental company for the model year and the fitness certificate for the machine. If the machine is not fit, any breakdown will cause delays and increase the overall project cost.

The control system of a backhoe is also different from an excavator. The backhoe uses two systems that are lever control and pilot control. The excavator has only a lever control option.

The pilot control uses buttons to maneuver the machine, while the two lever controls are used to move the backhoe. Some backhoe models have a unique joystick that allows the use of a loader and backhoe simultaneously. This feature is helpful when you want to reposition quickly or get unstuck.

The pilot controls are prevalent among the operators because the buttons are used to control the movement, and they are more comfortable to operate.

Expert’s Choice

We can use excavators and backhoes for different purposes. It depends on the project's requirement which machine is most efficient in a specific scenario. Remember the three most important factors when choosing heavy equipment for the project. These factors are:

- Project's Requirements

- Economy

- Terrain

If your project has both excavation and material shifting requirements, a backhoe loader would be preferred by an expert. You can save the costs of renting a loader. But this is not always the case. Let's say the project has a massive scope of excavation, and the project needs to be completed in less time. It would be best to use an excavator as it is much more efficient in large and deep excavations.

Backhoes are generally more economical than standard excavators because they offer excavation and debris removal. But if there is small landscaping, demolition, or sewer lines installation work, you can choose a mini excavator. A mini excavator's rental cost is much less than a backhoe.

If the construction site terrain is not leveled, the experts recommend hiring an excavator, as it is available with a track carrier.

Renting Heavy Equipment

After choosing an excavator or a backhoe for your project, the next step is to look for a reliable piece of equipment. A wide variety of excavators and backhoe loaders are available at Rent1 equipment rentals. You can hire a backhoe or excavator best suited for your project at the lowest rate from them.

The excavator rent starts from $450 per day while backhoe rent starts from $550 per day.

Hiring Heavy Equipment Operator

An experienced operator should only operate heavy equipment. There are many benefits to hiring a qualified operator. The most notable benefits are that they are highly efficient and can complete the work in less time.

The heavy equipment operators are highly skilled, and there are fewer chances of accidents when they are operating your machines.

You can also get discounts when you hire an operator with heavy equipment from Rent1 equipment rentals. The hourly rates for excavators and backhoes, including operators, range from $95 to $185 per hour.

Final thoughts

Excavators and backhoes are used for similar purposes but choosing the right equipment can optimize construction operations. You should evaluate the work scope carefully before deciding which one is the most suitable for your project.

If you have any questions about this post or heavy equipment you would like to know more about, contact us and we’ll get back to you as soon as we can.